- Diesel Forklift

-

- 25-30tonne Diesel Forklift 16T Forklift Truck 4.5 Ton Diesel Forklift 48 Ton Diesel Forklift 3 Ton Diesel Forklift 3.5 Ton Diesel Forklift 2.5 Ton Diesel Forklift 33 Ton Diesel Forklift 15 Ton Diesel Forklift 10 Ton Diesel Forklift 8 Ton Diesel Forklift 4 Ton Diesel Forklift 6Ton Forklift 2 Ton Diesel Forklift 1 Ton Diesel Forklift 1.8 Ton Diesel Forklift 1.5 Ton Diesel Forklift 7 ton forklift 35 ton Forklift Rough Terrain Forklift

- Electric Forklift

-

- Narrow Aisle Stand Up Counterbalance Forklift – High Efficiency Warehouse Solution 3.8ton Low Voltage Lithium Battery Forklift 12t Lithium high capacity forklift 12t large capacity electric forklift 8ton Electric Forklift 10t electric forklift truck 25ton Lithium Battery Forklift 7ton Electric Forklift 16-20t Large Capacity Lithium Battery Forklift 2 Ton Electric Forklift 1.8 Ton Electric Forklift 6 Ton Electric Forklift 1.5 Ton Electric Forklift 1.0-1.5 Ton Electric Forklift 2.5 Ton Electric Forklift 3.5 Ton Electric Forklift 4.0-4.5 Ton Electric Forklift 5 Ton Electric Forklift 3 Ton Electric Forklift 1.6-1.8Ton Three Wheel Electric Forklift 2 Ton three wheel electric forklift

- Rough Terrain Forklift

-

- 3.5t-4ton 4 wheel drive forklift 7 Ton All Rough Terrain Forklift 2-2.5T Rough Terrain Forklift Truck 4 ton off road forklift truck 3t 4 wheel drive forklift for sale 3.5t Two Wheel Drive Rough terrain forklift 3T Diesel Rough Terrain 2WD Forklift FLIFT 3.5ton all rough terrain forklift for sale 2WD 3t off Road Rough Terrain Forklift

- Electric Reach Truck & Pallet Truck / Pallet Stacker

-

- 5ton end rider electric pallet truck with customized 1.8m fork length 10ton-15ton heavy duty electric pallet truck 2.5ton all terrain electric pallet jack 1.5ton-2ton all terrain electric pallet truck with crane jib Counterbalanced Pallet Stacker 1600 lb to 2000 lb Capacity for Indoor Warehouses Heavy Duty 2T-2.5T Electric Stacker Forklift | High-Performance Stacker Lift High-Capacity 2.5t electric reach truck 1.0t -1.5t Electric Walkie Straddle Stacker 2ton Fully Electric Pallet Stacker 3 stage mast 2ton electric rough terrain pallet stacker 1.5ton off road Rough Terrain Stacker 1.8ton walkie Electric Pallet Truck Jack 1.5Ton Electric Pallet Stacker | Durable Walkie Stacker for Easy Material Handling 1200kg walking type electric pallet stacker 2ton roll and reel electric pallet truck Walkie Counterbalanced Stacker 1500–2000kg Capacity Compact Design 1ton outdoor rough terrain counterbalanced pallet stacker 3300lbs Electric off-road pallet stacker 2t Rough Terrain Pallet Truck Powered Pallet Truck with PU Wheels-2000kg Electric Pallet Jack 2t Elecric Hand Truck 1.5 Ton Electric Walkie Pallet Truck – Compact Power for Efficient Material Handling 2 Ton Reach Forklift 1.5 Ton Reach Forklift 2Ton -3Ton Electric Pallet Truck Semi-electric Pallet Stacker 1ton-1.6ton 3 Way Pallet Stacker Multi-Directional Sideloader Forklift 4 direction reach truck

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight Stacker Professional Walking Type Electric Stacker with Special Attachment 1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker 4t QDD40 Seated type Electric Tractor QDD60 Seated Type Fully Electric Tractor 3t QDD30C Electric Tractor with Turning Radius 1545mm 2t CQD20A Electric Simple Type Reach Forklift Truck 1.5t CQD15A Simple Type Electric Reach forklift Truck 5t Convertible Seated Electric Flat Truck 3t CBD30Z Electric Vehicle Transfer Truck 1.5t CDD15Y Electric Pallet Stacker (Rough Terrain) 1t CXD10-45 Electric High Lift-Order Picker 2t CQD20S-60 Four-way Walking Type Reach Forklift Truck CDD10A/15A Walking Type Fully Electric Pallet Stacker 3t QDD30A Standing Type Electric Tractor 1t CSD10 Man Mount Three-way Stacker 1.5t AGV type CDD15J-16 Electric Pallet Stacker CBD80 8t Electric Pallet Stacker 6t CBD60 Electric Pallet Stacker CBD120 1.2t Electric Pallet Stacker 2t CDD20D-30 Walking type Electric Pallet Staccker CDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper Fixture Fixed Short Arm non-sideshifting non-sideshifting Fixed Short Arm non-sideshifting Non-sideshifting Hinged Forks Caton Clamp Rotator non-Sideshifting Tire Clamps Pusher Turning Fork Clamps non-sideshifting Log Holder Sideshifting Broke Paper Clamps Sideshifting Sideshifting Single Load Stabilizer Fork Positioners Single Double Pallet Handler

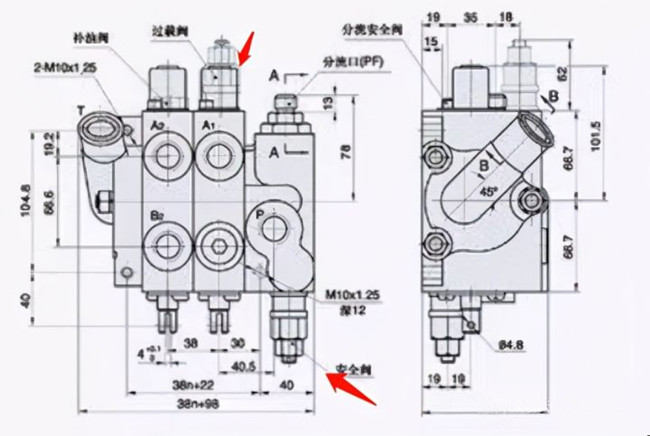

Forklift multi-way valve

Date: 2018-03-17 View:

.jpg)

.png)