- Diesel Forklift

-

- 25-30tonne Diesel Forklift 16T Forklift Truck 4.5 Ton Diesel Forklift 48 Ton Diesel Forklift 3 Ton Diesel Forklift 3.5 Ton Diesel Forklift 2.5 Ton Diesel Forklift 33 Ton Diesel Forklift 15 Ton Diesel Forklift 10 Ton Diesel Forklift 8 Ton Diesel Forklift 4 Ton Diesel Forklift 6Ton Forklift 2 Ton Diesel Forklift 1 Ton Diesel Forklift 1.8 Ton Diesel Forklift 1.5 Ton Diesel Forklift 7 ton forklift 35 ton Forklift Rough Terrain Forklift

- Electric Forklift

-

- Narrow Aisle Stand Up Counterbalance Forklift – High Efficiency Warehouse Solution 3.8ton Low Voltage Lithium Battery Forklift 12t Lithium high capacity forklift 12t large capacity electric forklift 8ton Electric Forklift 10t electric forklift truck 25ton Lithium Battery Forklift 7ton Electric Forklift 16-20t Large Capacity Lithium Battery Forklift 2 Ton Electric Forklift 1.8 Ton Electric Forklift 6 Ton Electric Forklift 1.5 Ton Electric Forklift 1.0-1.5 Ton Electric Forklift 2.5 Ton Electric Forklift 3.5 Ton Electric Forklift 4.0-4.5 Ton Electric Forklift 5 Ton Electric Forklift 3 Ton Electric Forklift 1.6-1.8Ton Three Wheel Electric Forklift 2 Ton three wheel electric forklift

- Rough Terrain Forklift

-

- 3.5t-4ton 4 wheel drive forklift 7 Ton All Rough Terrain Forklift 2-2.5T Rough Terrain Forklift Truck 4 ton off road forklift truck 3t 4 wheel drive forklift for sale 3.5t Two Wheel Drive Rough terrain forklift 3T Diesel Rough Terrain 2WD Forklift FLIFT 3.5ton all rough terrain forklift for sale 2WD 3t off Road Rough Terrain Forklift

- Electric Reach Truck & Pallet Truck / Pallet Stacker

-

- 5ton end rider electric pallet truck with customized 1.8m fork length 10ton-15ton heavy duty electric pallet truck 2.5ton all terrain electric pallet jack 1.5ton-2ton all terrain electric pallet truck with crane jib Counterbalanced Pallet Stacker 1600 lb to 2000 lb Capacity for Indoor Warehouses Heavy Duty 2T-2.5T Electric Stacker Forklift | High-Performance Stacker Lift High-Capacity 2.5t electric reach truck 1.0t -1.5t Electric Walkie Straddle Stacker 2ton Fully Electric Pallet Stacker 3 stage mast 2ton electric rough terrain pallet stacker 1.5ton off road Rough Terrain Stacker 1.8ton walkie Electric Pallet Truck Jack 1.5Ton Electric Pallet Stacker | Durable Walkie Stacker for Easy Material Handling 1200kg walking type electric pallet stacker 2ton roll and reel electric pallet truck Walkie Counterbalanced Stacker 1500–2000kg Capacity Compact Design 1ton outdoor rough terrain counterbalanced pallet stacker 3300lbs Electric off-road pallet stacker 2t Rough Terrain Pallet Truck Powered Pallet Truck with PU Wheels-2000kg Electric Pallet Jack 2t Elecric Hand Truck 1.5 Ton Electric Walkie Pallet Truck – Compact Power for Efficient Material Handling 2 Ton Reach Forklift 1.5 Ton Reach Forklift 2Ton -3Ton Electric Pallet Truck Semi-electric Pallet Stacker 1ton-1.6ton 3 Way Pallet Stacker Multi-Directional Sideloader Forklift 4 direction reach truck

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight Stacker Professional Walking Type Electric Stacker with Special Attachment 1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker 4t QDD40 Seated type Electric Tractor QDD60 Seated Type Fully Electric Tractor 3t QDD30C Electric Tractor with Turning Radius 1545mm 2t CQD20A Electric Simple Type Reach Forklift Truck 1.5t CQD15A Simple Type Electric Reach forklift Truck 5t Convertible Seated Electric Flat Truck 3t CBD30Z Electric Vehicle Transfer Truck 1.5t CDD15Y Electric Pallet Stacker (Rough Terrain) 1t CXD10-45 Electric High Lift-Order Picker 2t CQD20S-60 Four-way Walking Type Reach Forklift Truck CDD10A/15A Walking Type Fully Electric Pallet Stacker 3t QDD30A Standing Type Electric Tractor 1t CSD10 Man Mount Three-way Stacker 1.5t AGV type CDD15J-16 Electric Pallet Stacker CBD80 8t Electric Pallet Stacker 6t CBD60 Electric Pallet Stacker CBD120 1.2t Electric Pallet Stacker 2t CDD20D-30 Walking type Electric Pallet Staccker CDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper Fixture Fixed Short Arm non-sideshifting non-sideshifting Fixed Short Arm non-sideshifting Non-sideshifting Hinged Forks Caton Clamp Rotator non-Sideshifting Tire Clamps Pusher Turning Fork Clamps non-sideshifting Log Holder Sideshifting Broke Paper Clamps Sideshifting Sideshifting Single Load Stabilizer Fork Positioners Single Double Pallet Handler

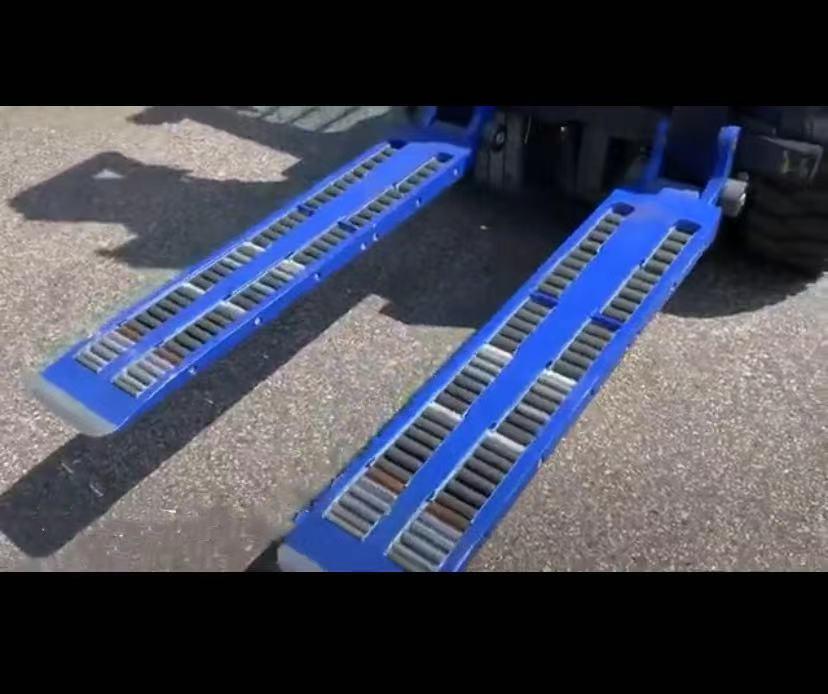

FLIFT Brand roller fork

Date: 2023-10-10 View:

In recent years, due to rising labor costs, raw material prices and environmental pressure, many enterprises are facing great challenges in cost management, among which the most obvious performance is some export enterprises. In order to solve these contradictions and problems, enterprises must abandon the old ideas and realize cost reduction through technological innovation and management efficiency. Here is a tool that can reduce the cost of logistics packaging and transportation for enterprises - cardless handling.

As we all know, the fork is a kind of forklift equipment, which is equivalent to the manipulator mounted on the forklift, so that the forklift becomes a multi-purpose and efficient material handling tool, which can fork, clamp, push, pull, side shift and rotation of almost any imaginable handling object, so as to improve logistics efficiency, reduce production costs, avoid product damage and save storage space. At present, the cargo fork is mostly used with the pallet, the goods are placed on the pallet, the cargo fork is inserted from the bottom of the pallet, and then the goods are transferred to the designated position, and then the cargo fork is drawn out, so repeated operation,

there is low work efficiency and increase the transportation cost.

How to achieve palletized handling of goods? This requires forklift accessories to determine what kind of fork accessories are equipped with forklifts mainly according to the different nature and different shapes of goods, and usually the use of ordinary forks is the most common. In view of the defects of low efficiency and high cost that the existing forklift fork must be equipped with pallets, a product designed for pallet-free handling of forklifts has appeared on the market, which is also called roller fork.

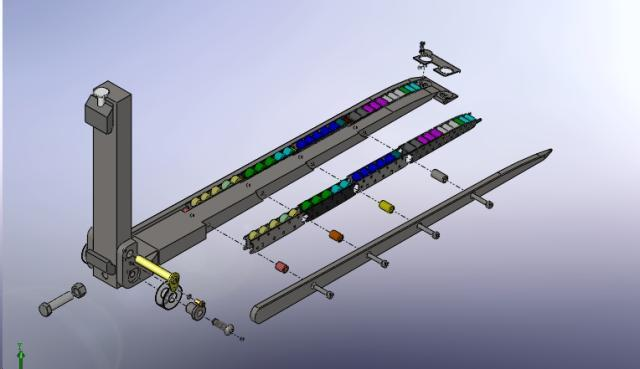

The principle of use is that when transferring some heavy or large coefficient of friction goods, the pin shaft is moved to the top pin shaft mounting hole, because the distance between the center of the upper pin shaft mounting hole and the top of the fork rod is less than the radius of the roller, at this time, the top of the roller wheel shows the roller groove and extends the top of the fork rod; Insert the fork rod from the bottom of the goods, through the rolling contact between the roller and the goods, so that the goods are inserted into the fork rod; Because the goods are heavy or the coefficient of friction is large, it is not easy to drop during the transit process; When unloading, similarly, pull the fork rod from the bottom of the roller; Thus, the traditional fork needs to be equipped with pallets, increasing the cost of equipment, and improving the flexibility of forklift, transfer and unloading.

When transporting some lighter or smaller coefficient of friction goods, it does not need the cooperation of rollers to facilitate the forklift, transfer and unloading of goods. Move the pin shaft into the lower pin shaft mounting hole

, and since the distance from the center of the lower pin shaft mounting hole to the top of the fork rod is greater than the radius of the roller, the roller is fully contained in the roller groove.

It can also realize the selective use or non-use of rollers for different goods, under the premise of meeting the convenience of forklift,transfer

and unloading, reduce the use of rollers, prevent excessive use of rollers, serious surface wear, and reduce its service life.

Usually in order to avoid damage to the goods or packaging boxes, a cardboard can be used under the goods, so that not only can avoid damage to the goods or cartons, but also can make the roller fork obtain better friction.

General bagged raw materials (such as chemical raw materials, plastic particles, etc.), export carton packaging products can use this roller fork to achieve handling. The advantages of the roller fork are easy to install, can be used in a variety of environments, and no need to frequently change the fork, environmental protection and efficiency, save pallets, reduce costs, for the export of container goods, save the space of the pallet, can put more goods.

.png)

.png)