- Diesel Forklift

-

- 25-30tonne Diesel Forklift 16T Forklift Truck 4.5 Ton Diesel Forklift 48 Ton Diesel Forklift 3 Ton Diesel Forklift 3.5 Ton Diesel Forklift 2.5 Ton Diesel Forklift 33 Ton Diesel Forklift 15 Ton Diesel Forklift 10 Ton Diesel Forklift 8 Ton Diesel Forklift 4 Ton Diesel Forklift 6Ton Forklift 2 Ton Diesel Forklift 1 Ton Diesel Forklift 1.8 Ton Diesel Forklift 1.5 Ton Diesel Forklift 7 ton forklift 35 ton Forklift Rough Terrain Forklift

- Electric Forklift

-

- Narrow Aisle Stand Up Counterbalance Forklift – High Efficiency Warehouse Solution 3.8ton Low Voltage Lithium Battery Forklift 12t Lithium high capacity forklift 12t large capacity electric forklift 8ton Electric Forklift 10t electric forklift truck 25ton Lithium Battery Forklift 7ton Electric Forklift 16-20t Large Capacity Lithium Battery Forklift 2 Ton Electric Forklift 1.8 Ton Electric Forklift 6 Ton Electric Forklift 1.5 Ton Electric Forklift 1.0-1.5 Ton Electric Forklift 2.5 Ton Electric Forklift 3.5 Ton Electric Forklift 4.0-4.5 Ton Electric Forklift 5 Ton Electric Forklift 3 Ton Electric Forklift 1.6-1.8Ton Three Wheel Electric Forklift 2 Ton three wheel electric forklift

- Rough Terrain Forklift

-

- 3.5t-4ton 4 wheel drive forklift 7 Ton All Rough Terrain Forklift 2-2.5T Rough Terrain Forklift Truck 4 ton off road forklift truck 3t 4 wheel drive forklift for sale 3.5t Two Wheel Drive Rough terrain forklift 3T Diesel Rough Terrain 2WD Forklift FLIFT 3.5ton all rough terrain forklift for sale 2WD 3t off Road Rough Terrain Forklift

- Electric Reach Truck & Pallet Truck / Pallet Stacker

-

- 5ton end rider electric pallet truck with customized 1.8m fork length 10ton-15ton heavy duty electric pallet truck 2.5ton all terrain electric pallet jack 1.5ton-2ton all terrain electric pallet truck with crane jib Counterbalanced Pallet Stacker 1600 lb to 2000 lb Capacity for Indoor Warehouses Heavy Duty 2T-2.5T Electric Stacker Forklift | High-Performance Stacker Lift High-Capacity 2.5t electric reach truck 1.0t -1.5t Electric Walkie Straddle Stacker 2ton Fully Electric Pallet Stacker 3 stage mast 2ton electric rough terrain pallet stacker 1.5ton off road Rough Terrain Stacker 1.8ton walkie Electric Pallet Truck Jack 1.5Ton Electric Pallet Stacker | Durable Walkie Stacker for Easy Material Handling 1200kg walking type electric pallet stacker 2ton roll and reel electric pallet truck Walkie Counterbalanced Stacker 1500–2000kg Capacity Compact Design 1ton outdoor rough terrain counterbalanced pallet stacker 3300lbs Electric off-road pallet stacker 2t Rough Terrain Pallet Truck Powered Pallet Truck with PU Wheels-2000kg Electric Pallet Jack 2t Elecric Hand Truck 1.5 Ton Electric Walkie Pallet Truck – Compact Power for Efficient Material Handling 2 Ton Reach Forklift 1.5 Ton Reach Forklift 2Ton -3Ton Electric Pallet Truck Semi-electric Pallet Stacker 1ton-1.6ton 3 Way Pallet Stacker Multi-Directional Sideloader Forklift 4 direction reach truck

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight Stacker Professional Walking Type Electric Stacker with Special Attachment 1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker 4t QDD40 Seated type Electric Tractor QDD60 Seated Type Fully Electric Tractor 3t QDD30C Electric Tractor with Turning Radius 1545mm 2t CQD20A Electric Simple Type Reach Forklift Truck 1.5t CQD15A Simple Type Electric Reach forklift Truck 5t Convertible Seated Electric Flat Truck 3t CBD30Z Electric Vehicle Transfer Truck 1.5t CDD15Y Electric Pallet Stacker (Rough Terrain) 1t CXD10-45 Electric High Lift-Order Picker 2t CQD20S-60 Four-way Walking Type Reach Forklift Truck CDD10A/15A Walking Type Fully Electric Pallet Stacker 3t QDD30A Standing Type Electric Tractor 1t CSD10 Man Mount Three-way Stacker 1.5t AGV type CDD15J-16 Electric Pallet Stacker CBD80 8t Electric Pallet Stacker 6t CBD60 Electric Pallet Stacker CBD120 1.2t Electric Pallet Stacker 2t CDD20D-30 Walking type Electric Pallet Staccker CDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper Fixture Fixed Short Arm non-sideshifting non-sideshifting Fixed Short Arm non-sideshifting Non-sideshifting Hinged Forks Caton Clamp Rotator non-Sideshifting Tire Clamps Pusher Turning Fork Clamps non-sideshifting Log Holder Sideshifting Broke Paper Clamps Sideshifting Sideshifting Single Load Stabilizer Fork Positioners Single Double Pallet Handler

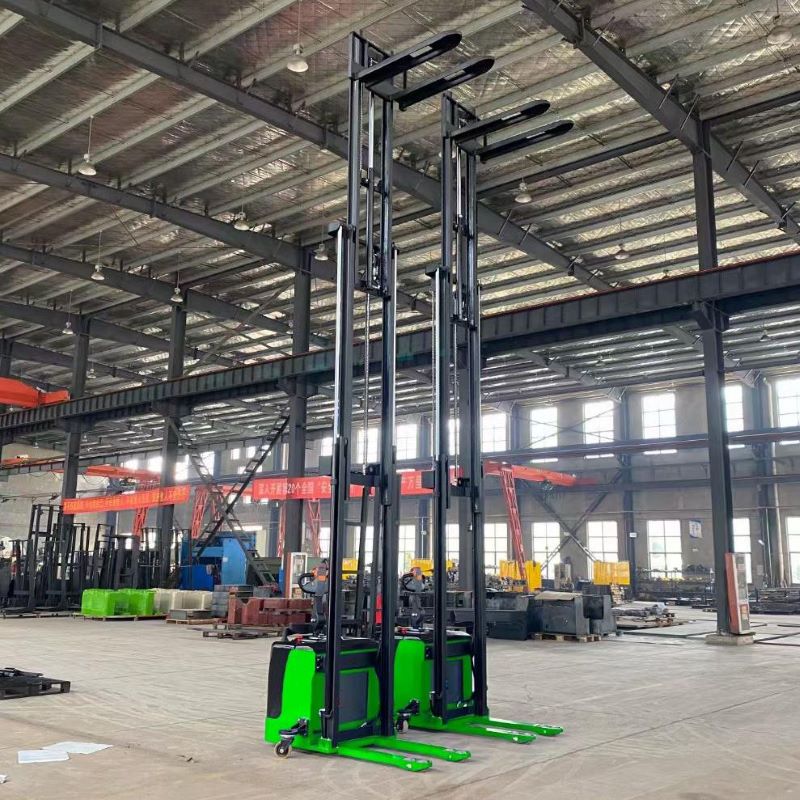

Electric counterbalance stacker warehouse equipment counterbalanced electric pallet stacker factory price for sale

Date: 2025-05-12 View:

What is the difference between

counterbalanced stackers and ordinary electric stackers?

Before we start analyzing the difference between a counterbalanced stacker and an ordinary electric stacker, let's first learn what a counterbalanced stacker is?

A counterbalanced stacker is a common industrial handling vehicle, mainly used for stacking, loading and unloading, and short-distance transportation of goods.

It mainly relies on the counterbalanced weight block at the rear of the vehicle to balance the forward tilting torque generated when the fork lifts the goods, so that the vehicle remains stable during operation and prevents forward tilting and overturning.

When the fork carries the goods and rises, the center of gravity of the vehicle will move forward, and the role of the counterbalanced weight block is to maintain the overall center of gravity of the vehicle within a stable range to ensure the safety and stability of the vehicle.

Let's analyze the differences between a counterbalanced stacker and an ordinary electric stacker from several aspects.

The first is from the structural design. The counterbalanced stacker has a counterbalanced weight block installed at the rear of the vehicle body to balance the torque generated when the fork lifts the goods, ensuring the stability of the vehicle during operation and loading and unloading.

Ordinary electric stackers usually adopt a more compact structural design.

Some models may not have a special counterweight, but achieve a certain degree of balance by reasonably distributing components such as batteries and motors.

Secondly, let's look at the load capacity. Counterbalanced stackers generally have a large load capacity.

Common models can carry 1.5-5 tons of goods, and some large counterbalanced stackers can even carry heavier goods.

The load capacity of ordinary electric stackers is relatively small, generally around 1-2 tons, suitable for stacking and handling lighter goods.

Thirdly, let's look at the lifting height. The lifting height of counterbalanced stackers is usually high, generally up to 3-6 meters, and some special models can even be higher, which can meet the stacking needs of goods on shelves of different heights.

The lifting height of ordinary electric stackers is generally around 2-4 meters, mainly suitable for some warehouse shelves or work scenes with relatively low heights.

At present, the maximum lifting height of FLIFT's ordinary stackers can reach 7 meters.

Finally, let's analyze it from the perspective of driving speed.The driving speed of counterbalanced stackers is relatively fast, especially when fully loaded, they can still maintain a certain driving speed, which helps to improve the efficiency of cargo handling.

Ordinary electric stackers usually have a slower driving speed, mainly to ensure the safety and accuracy of operation, and are more suitable for some occasions where speed is not required.

So what are the advantages of counterbalanced stackers compared to ordinary stackers or other storage trucks?

Powerful load and lifting capacity: counterbalanced stackers can carry heavier goods and lift them to a higher height, which makes them suitable for stacking and storing various heavy goods, such as large machinery and equipment, pallet goods, etc.

In large warehouses, logistics centers and other places, when a large amount of heavy goods needs to be handled and stacked, counterbalanced stackers can play their advantages, reduce the number of handling times, and improve work efficiency.

Good stability: Due to the use of counterbalanced weight design, counterbalanced stackers have excellent stability during operation.

Whether it is fully loaded, turning or lifting goods, it can effectively prevent the vehicle from tipping over and ensure the safety of operators and goods.

This advantage enables it to operate stably in various complex working environments and adapt to different operating requirements.

High operating efficiency: Faster driving speed and higher lifting speed enable the counterbalanced stacker to save a lot of time in the process of cargo handling.

At the same time, its larger load capacity can reduce the batches of cargo handled each time, further improving operating efficiency.

In some companies with high requirements for logistics efficiency, counterbalanced stackers can better meet the needs of rapid turnover.

Wide applicability: Counterbalanced stackers can be equipped with a variety of accessories, such as forks, lifting arms, rotating clamps, etc., to meet the handling and stacking needs of different types of goods.

Whether it is conventional pallet cargo or irregularly shaped cargo, the operation can be completed by replacing the corresponding accessories, which greatly improves the versatility and applicability of the equipment.

The following is a case of FLIFT custom electric counterbalanced stacker:

With paper roll clamp

With carton clamp

With bale clamp

With boom Attachment

What safety protection devices does the electric counterbalanced stacker have?

Taking FLIFT as an example, it is equipped with automatic deceleration of the fork high cargo position, multiple automatic protection systems of the controller, emergency reverse anti-collision device and automatic deceleration device for curves.

The high-position automatic deceleration device of the fork automatically reduces the travel speed by 30%-50% when the fork is raised to a high position with the help of high-precision sensors and intelligent algorithms, reducing the risk of shaking during high-position operations and cargo falling.

The controller's multiple automatic protection systems integrate overload, short circuit and abnormal power-off protection.

If the load exceeds the standard, it will immediately alarm and lock. If the circuit is abnormal, the power will be cut off in 0.1 seconds.

Sudden power off can also ensure the smooth and slow descent of the fork.

The emergency reverse anti-collision device uses dual detection of infrared and millimeter-wave radars, 360° real-time scanning, and triggers emergency reverse escape within 0.5 seconds when encountering obstacles.

The automatic deceleration device for curves uses gyroscopes and speed sensors to accurately sense steering, automatically reduce speed and cooperate with anti-rollover design to ensure smooth driving on curves.

.png)