- Diesel Forklift

-

- 25-30tonne Diesel Forklift 16T Forklift Truck 4.5 Ton Diesel Forklift 48 Ton Diesel Forklift 3 Ton Diesel Forklift 3.5 Ton Diesel Forklift 2.5 Ton Diesel Forklift 33 Ton Diesel Forklift 15 Ton Diesel Forklift 10 Ton Diesel Forklift 8 Ton Diesel Forklift 4 Ton Diesel Forklift 6Ton Forklift 2 Ton Diesel Forklift 1 Ton Diesel Forklift 1.8 Ton Diesel Forklift 1.5 Ton Diesel Forklift 7 ton forklift 35 ton Forklift Rough Terrain Forklift

- Electric Forklift

-

- Narrow Aisle Stand Up Counterbalance Forklift – High Efficiency Warehouse Solution 3.8ton Low Voltage Lithium Battery Forklift 12t Lithium high capacity forklift 12t large capacity electric forklift 8ton Electric Forklift 10t electric forklift truck 25ton Lithium Battery Forklift 7ton Electric Forklift 16-20t Large Capacity Lithium Battery Forklift 2 Ton Electric Forklift 1.8 Ton Electric Forklift 6 Ton Electric Forklift 1.5 Ton Electric Forklift 1.0-1.5 Ton Electric Forklift 2.5 Ton Electric Forklift 3.5 Ton Electric Forklift 4.0-4.5 Ton Electric Forklift 5 Ton Electric Forklift 3 Ton Electric Forklift 1.6-1.8Ton Three Wheel Electric Forklift 2 Ton three wheel electric forklift

- Rough Terrain Forklift

-

- 3.5t-4ton 4 wheel drive forklift 7 Ton All Rough Terrain Forklift 2-2.5T Rough Terrain Forklift Truck 4 ton off road forklift truck 3t 4 wheel drive forklift for sale 3.5t Two Wheel Drive Rough terrain forklift 3T Diesel Rough Terrain 2WD Forklift FLIFT 3.5ton all rough terrain forklift for sale 2WD 3t off Road Rough Terrain Forklift

- Electric Reach Truck & Pallet Truck / Pallet Stacker

-

- 5ton end rider electric pallet truck with customized 1.8m fork length 10ton-15ton heavy duty electric pallet truck 2.5ton all terrain electric pallet jack 1.5ton-2ton all terrain electric pallet truck with crane jib Counterbalanced Pallet Stacker 1600 lb to 2000 lb Capacity for Indoor Warehouses Heavy Duty 2T-2.5T Electric Stacker Forklift | High-Performance Stacker Lift High-Capacity 2.5t electric reach truck 1.0t -1.5t Electric Walkie Straddle Stacker 2ton Fully Electric Pallet Stacker 3 stage mast 2ton electric rough terrain pallet stacker 1.5ton off road Rough Terrain Stacker 1.8ton walkie Electric Pallet Truck Jack 1.5Ton Electric Pallet Stacker | Durable Walkie Stacker for Easy Material Handling 1200kg walking type electric pallet stacker 2ton roll and reel electric pallet truck Walkie Counterbalanced Stacker 1500–2000kg Capacity Compact Design 1ton outdoor rough terrain counterbalanced pallet stacker 3300lbs Electric off-road pallet stacker 2t Rough Terrain Pallet Truck Powered Pallet Truck with PU Wheels-2000kg Electric Pallet Jack 2t Elecric Hand Truck 1.5 Ton Electric Walkie Pallet Truck – Compact Power for Efficient Material Handling 2 Ton Reach Forklift 1.5 Ton Reach Forklift 2Ton -3Ton Electric Pallet Truck Semi-electric Pallet Stacker 1ton-1.6ton 3 Way Pallet Stacker Multi-Directional Sideloader Forklift 4 direction reach truck

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight Stacker Professional Walking Type Electric Stacker with Special Attachment 1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker 4t QDD40 Seated type Electric Tractor QDD60 Seated Type Fully Electric Tractor 3t QDD30C Electric Tractor with Turning Radius 1545mm 2t CQD20A Electric Simple Type Reach Forklift Truck 1.5t CQD15A Simple Type Electric Reach forklift Truck 5t Convertible Seated Electric Flat Truck 3t CBD30Z Electric Vehicle Transfer Truck 1.5t CDD15Y Electric Pallet Stacker (Rough Terrain) 1t CXD10-45 Electric High Lift-Order Picker 2t CQD20S-60 Four-way Walking Type Reach Forklift Truck CDD10A/15A Walking Type Fully Electric Pallet Stacker 3t QDD30A Standing Type Electric Tractor 1t CSD10 Man Mount Three-way Stacker 1.5t AGV type CDD15J-16 Electric Pallet Stacker CBD80 8t Electric Pallet Stacker 6t CBD60 Electric Pallet Stacker CBD120 1.2t Electric Pallet Stacker 2t CDD20D-30 Walking type Electric Pallet Staccker CDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper Fixture Fixed Short Arm non-sideshifting non-sideshifting Fixed Short Arm non-sideshifting Non-sideshifting Hinged Forks Caton Clamp Rotator non-Sideshifting Tire Clamps Pusher Turning Fork Clamps non-sideshifting Log Holder Sideshifting Broke Paper Clamps Sideshifting Sideshifting Single Load Stabilizer Fork Positioners Single Double Pallet Handler

Can we install the tire attachment on the 3.5t diesel forklift?

Date: 2024-11-29 View:

FLIFT Brand 3.5T Diesel Forklift

The perfect combination of powerful power and efficient equipment"

Overview of FLIFT brand 3.5T diesel forklift.

FLIFT 3.5T diesel forklift with its excellent performance and high-quality configuration plays an important role in logistics, warehousing and other fields.

This article details the features of this forklift truck, including the Cummins engine and tire clamp fittings.

The FLIFT 3.5T diesel forklift is the go-to truck for the logistics and warehousing industry.

Its emergence provides an efficient and reliable solution for the cargo handling and storage of enterprises.

The exceptional performance of this forklift is due to its careful design and high-quality configuration,

of which Cummins engine and tire clamp fittings are two of its highlights.

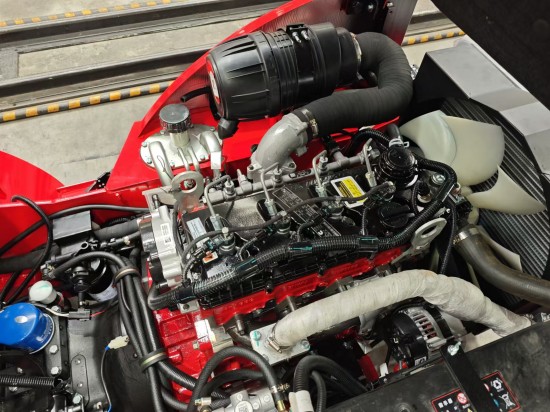

(1) Cummins engine

1. Model and performance

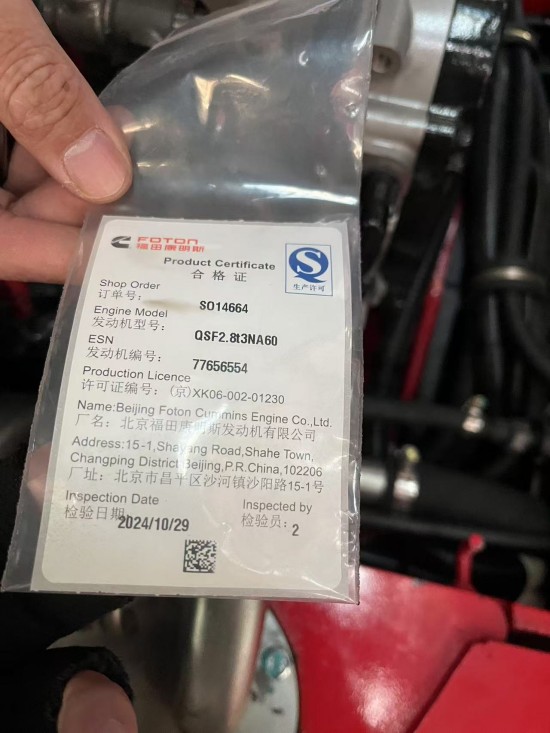

The FLIFT 3.5T diesel forklift is equipped with Cummins engine model QSF2.8, which is a turbocharged diesel engine.

It has more powerful power and excellent fuel saving performance,

which provides a solid guarantee for the efficient operation of forklift trucks.

Cummins engines enjoy a high reputation in the industry for their advanced technology and reliable quality. It uses turbocharging technology,

which can increase the combustion efficiency while increasing the engine intake,

so that the output of more powerful power.

The dynamic performance of this engine can not only meet the needs of forklifts in heavy load situations,

but also maintain stable operation in a variety of complex working environments.

In terms of fuel economy, the Cummins QSF2.8 engine also performs well. By optimizing the fuel injection system and combustion process,

it reduces fuel consumption and saves users operating costs.

At the same time, this engine also has good environmental performance, emissions in line with relevant standards, reducing environmental pollution.

2. How it works

Cummins engines work by burning diesel to generate power. It consists of cylinder, piston, crankshaft, connecting rod and other components.

During the working process, the diesel oil is compressed and ignited in the cylinder,

and the generated high temperature and high pressure gas pushes the piston movement,

transmits the power to the crankshaft through the connecting rod, and finally drives the forklift truck.

Cummins engine adopts advanced fuel injection technology and intelligent control system,

which can accurately control the injection amount and injection time of fuel,

improve combustion efficiency and reduce fuel consumption.

At the same time, it also has good heat dissipation performance and reliability, and can maintain stable operation in a long time of work.

3. Fuel saving methods

In order to further improve the fuel saving performance of Cummins engines, users can take the following methods:

(1) Drive reasonably. Avoid slamming on the accelerator and braking, try to keep a constant speed and reduce excessive acceleration and deceleration.

This reduces the load on the engine and reduces fuel consumption.

(2) Select the best speed. According to the vehicle type, road conditions and other factors, choose the best speed. A lower speed will add additional fuel consumption,

while a higher speed will increase wind resistance and air resistance, affecting fuel efficiency.

(3) Reasonable loading. Do not exceed the range of vehicle carrying capacity, avoid excessive loading or unbalanced load,

in order to reduce engine load and reduce fuel consumption.

(4) Check the engine regularly. Keeping the engine clean and well-adjusted fuel injection pump, fuel supply system, air filter, etc.,

can improve fuel efficiency and reduce fuel consumption.

(5) Appropriately reduce the use of electronic equipment. Try to avoid turning on air conditioning, audio,

car refrigerator and other electronic equipment for a long time to reduce engine load and reduce fuel consumption.

4. Parameter Description

The tire clamp fittings of the FLIFT 3.5T diesel forklift have the following parameters: load capacity of 400 kg, arm range of 800-1700MM, 360° rotation.

These parameters give the tire clamp a high degree of efficiency and flexibility when handling and stacking goods such as tires.

The capacity to carry 400 kg can meet the handling needs of most tires.

The arm range of 800-1700MM can be adapted to different tire sizes, improving the versatility of the fittings.

The 360° rotation function makes the forklift more flexible in the operation process, and can complete the handling and stacking of goods in a small space.

5. Feature analysis

(1) Smart clamp arm design, smooth surface, small thickness, easy to operate in small space, reduce tire damage.

The clamp arm design of the tire clamp fittings is very clever, smooth surface and small thickness.

This design allows the fittings to better adapt to small Spaces during operation, avoid collisions with surrounding objects, and reduce tire damage.

(2) Two-way 360° rotation, any Angle self-locking, improve safety performance.

The tire clamp has a two-way 360° rotation function and can be self-locked at any Angle.

This not only improves the operational flexibility of the forklift, but also improves the safety performance,

ensuring that the goods will not be accidentally dropped during handling.

(3) The hydraulic components are reasonably designed and durable.

The hydraulic components of the tire clamp fittings are designed reasonably, using high-quality materials and advanced manufacturing technology,

with good sealing and reliability.

This enables the appliance to maintain stable performance and durability over a long period of use.

(4) Compact structure, light weight, increase the service life of forklift. Compact structure and light weight of tire clamp fittings.

Such a design will not bring too much burden to the forklift, reduce the wear of the forklift, and increase the service life of the forklift.

6. Application field

Tire clamping equipment can safely and efficiently pallet-free handling and stacking of various tires,

reducing labor intensity, saving a lot of storage space,

and improving work efficiency.

It is widely used in tire production enterprises, automobile repair plants, logistics warehousing and other fields.

In tire production enterprises, tire clamp fittings can be used for handling and stacking finished tires to improve production efficiency.

In the car repair shop, it can easily handle and replace car tires, reducing the labor intensity of workers.

In the field of logistics warehousing, tire clamp fittings can be used to store and handle tires and other goods,

saving storage space and improving the utilization rate of the warehouse.

Two, Cummins QSF2.8 engine

(1) Strong power output

The Cummins QSF2.8 engine, as a turbocharged diesel engine, shows a remarkable power output. With its high horsepower and torque,

it provides the FLIFT brand 3.5T diesel forklift with an abundant source of power, ensuring efficient operation in a wide range of complex operating conditions.

It can be seen from the writing material that the Cummins 2.8 engine has high reliability and stability, which is suitable for heavy duty vehicles,

industrial, electric power and transportation.

Cummins QSF2.8 engine also has these advantages,

its use of advanced combustion technology and turbocharging system, can increase the engine intake while increasing combustion efficiency,

resulting in powerful power output.

For example, the Cummins QSF2.8 engine is able to easily handle heavy loads when powering a forklift,

maintaining a consistent power output whether it's lifting heavy loads or driving on bumpy roads.

(2) Fuel saving performance

The Cummins QSF2.8 engine is excellent in terms of fuel economy. It adopts advanced combustion technology and optimized fuel injection system,

which can accurately control the injection amount and injection time of fuel,

improve combustion efficiency and reduce fuel consumption.

As mentioned in the writing material, the Cummins 2.8 engine has good fuel economy while maintaining strong power.

It has a lower fuel consumption rate than other comparable products,

helping to reduce operating costs.

For companies using the FLIFT brand 3.5T diesel forklifts, this means significant savings in fuel costs and improved economic efficiency.

In addition, reasonable driving of forklift trucks can further improve the fuel saving performance of Cummins engines.

Avoid stepping on the accelerator and braking sharply, try to maintain a uniform speed, reduce excessive acceleration and deceleration,

which can reduce the load of the engine and reduce fuel consumption.

At the same time, the optimal speed is selected according to the vehicle type,

road conditions and other factors to avoid additional fuel consumption caused by lower or higher speeds.

Reasonable loading of goods does not exceed the carrying capacity of the vehicle, avoid excessive loading or unbalanced load,

but also reduce the engine load and reduce fuel consumption. Regular inspection of the engine,

keeping it clean and well-adjusted fuel injection pumps, fuel supply systems, air filters, etc.,

can also improve fuel efficiency and reduce fuel consumption.

Appropriately reduce the use of electronic equipment, avoid opening air conditioning, audio,

car refrigerator and other electronic equipment for a long time,

but also reduce the engine load, reduce fuel consumption.

(3) Reliability and durability

Cummins engines are known for their high reliability and long life, and the Cummins QSF2.8 engine is no exception.

This engine has been rigorously tested and proven to withstand long periods of intensive work,

reducing the frequency of maintenance and replacement.

As you can see from the writing material, Cummins' 2.8-liter engine is designed to be very robust and can withstand harsh working conditions for long periods of time.

It uses high-quality materials and superb manufacturing processes, with high durability and reliability. Cummins QSF2.8 engine in the use of forklift truck,

can withstand various tests, whether it is a long time continuous work or in harsh working environment, can maintain stable performance.

In addition, the compact structure of the Cummins QSF2.8 engine and the versatility of the components are also high,

which makes repair and maintenance more convenient and economical.

When the engine fails, the maintenance personnel can more easily find the right parts to replace,

shorten the maintenance time and reduce the maintenance cost.

(4) Low noise and environmental performance

Cummins QSF2.8 engine uses advanced noise reduction technology, operating noise is relatively low, improve the driver's working comfort.

At the same time, the engine meets strict emission standards and is environmentally friendly.

The Cummins 2.8 engine uses advanced noise reduction technology, making it run relatively noise-free.

This feature is also reflected in the Cummins QSF2.8 engine.

In the process of forklift operation, the low-noise engine can reduce the driver's fatigue and improve the work efficiency.

At the same time, the low noise also helps to reduce noise pollution,

resulting in a better experience for the surrounding staff and the environment.

In terms of environmental performance, the Cummins QSF2.8 engine meets stringent emission standards.

It uses advanced emission control technologies such as selective catalytic reduction (SCR) and particle traps (DPF),

allowing its emission levels to meet or exceed stringent environmental standards.

This is of great significance for protecting the environment and reducing air pollution.

With the continuous improvement of environmental requirements,

the environmental performance of Cummins QSF2.8 engine will become a major advantage in the market.

Third, tire clamp fittings.

(1) Parameter introduction

7. The load is 400 kg, which can meet the handling needs of most tires. In the actual tire handling scenario, whether it is a small car tire or a medium truck tire,

the 400 kg load capacity ensures a safe and stable handling operation.

This load parameter has been strictly tested and verified in practical applications, and fully considers the weight differences of various types of tires,

providing users with reliable handling guarantees.

8. The arm range is 800-1700MM, which can adapt to different sizes of tires.

The arm range of 800-1700MM is highly flexible and can cover a wide range of sizes from car tires to tires for large engineering vehicles.

This design makes it easy for the tire clamp to cope with different tire specifications without frequent replacement of the tire, improving work efficiency. For example,

in the car repair shop, whether the tire of a small car or the tire of an SUV, it can be firmly clamped and carried within this arm range.

9. 360° rotation, easy operation, improve work efficiency.

The 360° rotation function brings great convenience to the forklift operation

. In a tight space, the forklift driver can easily adjust the direction of the tire, placing it exactly where it needs to be.

Whether between shelves in a warehouse or in a narrow shop aisle,

this feature can be used to great advantage.

At the same time, 360° rotation also makes the stacking of tires more efficient, and can quickly complete the storage and sorting of tires.

(2) Advantage analysis

10. Improve work efficiency: tire clamping equipment can quickly and accurately clamp and carry tires, reducing the time and labor intensity of manual operation.

Compared with the traditional manual handling method, the tire clamping equipment can complete more handling tasks in a shorter time.

For example, in tire production enterprises, the use of tire clamping fittings can greatly improve the handling speed of finished tires, thereby speeding up the production process.

In the field of logistics warehousing,

rapid tire handling can improve the turnover rate of the warehouse and reduce the backlog of goods.

11. Safe and reliable: The design of the accessories ensures the stability and safety of the tires during handling, reducing the risk of accidents.

The clamping arm of the tire clamping device has the advantages of clever design, smooth surface and small thickness,

which can reduce the damage to the tire when holding the tire. At the same time,

the two-way 360° rotation function can self-lock at any Angle to ensure that the tire will not accidentally drop during handling.

In addition, the hydraulic components are reasonably designed and durable,

which can ensure the stable performance of the accessories and further improve the safety of handling.

12. Strong versatility: suitable for various types of forklifts, convenient for users to select and configure according to different needs.

Different types of forklifts can be equipped with tire clamp fittings in different working scenarios, which improves the versatility of the equipment.

Whether it is an internal combustion forklift or an electric forklift, the appropriate tire clamp fittings can be selected according to the actual needs to meet different handling tasks.

This versatility allows users to be more flexible when purchasing and using equipment, which can be adjusted and configured according to specific work needs.

The FLIFT brand 3.5T diesel forklift occupies an important position in the logistics industry with its outstanding characteristics and advantages.

The excellent performance of Cummins engine and tire clamp fittings provides users with an efficient and reliable logistics solution.

The features of the FLIFT 3.5T diesel forklift are mainly reflected in the following aspects:

First, the Cummins QSF2.8 turbocharged diesel engine has a strong power output, which can meet the needs of a variety of complex working conditions.

Whether it is heavy load handling or driving on rough roads, it can maintain stable power.

Secondly, the engine performs well in terms of fuel economy, using advanced combustion technology

and optimized fuel injection system to reduce fuel consumption and save operating costs for users.

At the same time, Cummins engines are known for their high reliability and durability,

and have been rigorously tested and proven to withstand long periods of high-intensity work,

reducing the frequency of maintenance and replacement.

In addition, low noise and environmental performance is also one of its advantages, the use of advanced noise reduction technology,

relatively low operating noise,

improve the driver's working comfort, and meet strict emission standards, environmentally friendly.

Tire clamp fittings are also a highlight of FLIFT brand forklifts.

Can we install the tire attachment on the 3.5t diesel forklift?

Yes, the tire attachment could be customized as demand, install on the forklift to carry the tires.

Can diesel forklift could be equipped with Cascade brand paper roll clamp?

Yes, no problem. Not only equip with Cascade brand attachment,

but also could add the china brand forklift attachments.

Can the 3.5t diesel forklift be equipped with Cummins or Mitsubishi engine?

Yes, in general, we equip with china brand engine.But the engine brand is optional,

such as the America Cummins Engine and Japanese Isuzu and Mitsubishi engine.

Join us as we explore the features and capabilities of the cutting-edge 3.5t Diesel Forklift featuring a Cascade Paper Roll Clamp!

This video showcases its remarkable lifting height of up to 5000mm,

robust clamp capacity of 2200kg,

and adjustable open range between 200-1400mm—all enhanced by a smooth-operating Mitsubishi S4S diesel engine.

See it in action with its unique rotating function that makes handling paper rolls effortless!

Click to watch!

.png)