- Diesel Forklift

-

- 25-30tonne Diesel Forklift 16T Forklift Truck 4.5 Ton Diesel Forklift 48 Ton Diesel Forklift 3 Ton Diesel Forklift 3.5 Ton Diesel Forklift 2.5 Ton Diesel Forklift 33 Ton Diesel Forklift 15 Ton Diesel Forklift 10 Ton Diesel Forklift 8 Ton Diesel Forklift 4 Ton Diesel Forklift 6Ton Forklift 2 Ton Diesel Forklift 1 Ton Diesel Forklift 1.8 Ton Diesel Forklift 1.5 Ton Diesel Forklift 7 ton forklift 35 ton Forklift Rough Terrain Forklift

- Electric Forklift

-

- Narrow Aisle Stand Up Counterbalance Forklift – High Efficiency Warehouse Solution 3.8ton Low Voltage Lithium Battery Forklift 12t Lithium high capacity forklift 12t large capacity electric forklift 8ton Electric Forklift 10t electric forklift truck 25ton Lithium Battery Forklift 7ton Electric Forklift 16-20t Large Capacity Lithium Battery Forklift 2 Ton Electric Forklift 1.8 Ton Electric Forklift 6 Ton Electric Forklift 1.5 Ton Electric Forklift 1.0-1.5 Ton Electric Forklift 2.5 Ton Electric Forklift 3.5 Ton Electric Forklift 4.0-4.5 Ton Electric Forklift 5 Ton Electric Forklift 3 Ton Electric Forklift 1.6-1.8Ton Three Wheel Electric Forklift 2 Ton three wheel electric forklift

- Rough Terrain Forklift

-

- 3.5t-4ton 4 wheel drive forklift 7 Ton All Rough Terrain Forklift 2-2.5T Rough Terrain Forklift Truck 4 ton off road forklift truck 3t 4 wheel drive forklift for sale 3.5t Two Wheel Drive Rough terrain forklift 3T Diesel Rough Terrain 2WD Forklift FLIFT 3.5ton all rough terrain forklift for sale 2WD 3t off Road Rough Terrain Forklift

- Electric Reach Truck & Pallet Truck / Pallet Stacker

-

- 5ton end rider electric pallet truck with customized 1.8m fork length 10ton-15ton heavy duty electric pallet truck 2.5ton all terrain electric pallet jack 1.5ton-2ton all terrain electric pallet truck with crane jib Counterbalanced Pallet Stacker 1600 lb to 2000 lb Capacity for Indoor Warehouses Heavy Duty 2T-2.5T Electric Stacker Forklift | High-Performance Stacker Lift High-Capacity 2.5t electric reach truck 1.0t -1.5t Electric Walkie Straddle Stacker 2ton Fully Electric Pallet Stacker 3 stage mast 2ton electric rough terrain pallet stacker 1.5ton off road Rough Terrain Stacker 1.8ton walkie Electric Pallet Truck Jack 1.5Ton Electric Pallet Stacker | Durable Walkie Stacker for Easy Material Handling 1200kg walking type electric pallet stacker 2ton roll and reel electric pallet truck Walkie Counterbalanced Stacker 1500–2000kg Capacity Compact Design 1ton outdoor rough terrain counterbalanced pallet stacker 3300lbs Electric off-road pallet stacker 2t Rough Terrain Pallet Truck Powered Pallet Truck with PU Wheels-2000kg Electric Pallet Jack 2t Elecric Hand Truck 1.5 Ton Electric Walkie Pallet Truck – Compact Power for Efficient Material Handling 2 Ton Reach Forklift 1.5 Ton Reach Forklift 2Ton -3Ton Electric Pallet Truck Semi-electric Pallet Stacker 1ton-1.6ton 3 Way Pallet Stacker Multi-Directional Sideloader Forklift 4 direction reach truck

- Customization Forklift

-

- 900kg CDD09B Electric Walking Type Counterweight Stacker Professional Walking Type Electric Stacker with Special Attachment 1ton Electric Outdoor Rough Terrain Telescopic Spreader Stacker 4t QDD40 Seated type Electric Tractor QDD60 Seated Type Fully Electric Tractor 3t QDD30C Electric Tractor with Turning Radius 1545mm 2t CQD20A Electric Simple Type Reach Forklift Truck 1.5t CQD15A Simple Type Electric Reach forklift Truck 5t Convertible Seated Electric Flat Truck 3t CBD30Z Electric Vehicle Transfer Truck 1.5t CDD15Y Electric Pallet Stacker (Rough Terrain) 1t CXD10-45 Electric High Lift-Order Picker 2t CQD20S-60 Four-way Walking Type Reach Forklift Truck CDD10A/15A Walking Type Fully Electric Pallet Stacker 3t QDD30A Standing Type Electric Tractor 1t CSD10 Man Mount Three-way Stacker 1.5t AGV type CDD15J-16 Electric Pallet Stacker CBD80 8t Electric Pallet Stacker 6t CBD60 Electric Pallet Stacker CBD120 1.2t Electric Pallet Stacker 2t CDD20D-30 Walking type Electric Pallet Staccker CDD08B-25 Counterweight Electric Pallet Stacker

- Forklift Attachements

-

- Waste Paper Fixture Fixed Short Arm non-sideshifting non-sideshifting Fixed Short Arm non-sideshifting Non-sideshifting Hinged Forks Caton Clamp Rotator non-Sideshifting Tire Clamps Pusher Turning Fork Clamps non-sideshifting Log Holder Sideshifting Broke Paper Clamps Sideshifting Sideshifting Single Load Stabilizer Fork Positioners Single Double Pallet Handler

Rise Above with FLIFT's 7m Lift: The Ultimate Telehandler Experience!"

Date: 2025-05-21 View:

.png)

Here is a brief introduction to some main configurations as follows.

Lifting height: 7000mm,

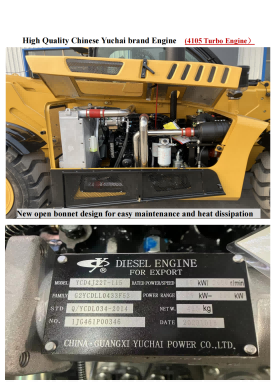

Equipped with China's famous YUCHAI brand Diesel engine, Engine power: 85kw,

We could also choose the Cummins engine.

(Electronic proportional valve with handle)

A high-power air-conditioner is the standard configuration which installed in the rear cabin.

What are the advantages of an electronic proportional valve with a handle?

An electronic proportional valve with a handle is a precision control system that allows the operator to adjust hydraulic functions smoothly and accurately.

It's commonly used in advanced telehandlers and forklifts to manage attachments such as booms, forks, clamps, and buckets.

Here are the key benefits of a telehandler forklift:

Smooth and Precise Control,

The electronic proportional valve enables gradual, fine-tuned movements, unlike traditional mechanical valves that may feel jerky or hard to control.

This is especially important when operating attachments at height or working in tight spaces where precision matters.

Improved Operator Comfort,

With an ergonomic handle and easy fingertip operation, operators experience less fatigue during long working hours.

The handle's responsiveness gives a more natural feel, reducing strain and improving the user experience.

Better Safety and Higher Productivity.

Smooth movement reduces the risk of sudden jolts or misoperation, which can cause load instability.

This added control leads to safer load handling, particularly when working on uneven ground or around people.

Whether you're lifting pallets, extending a boom, or tilting an attachment, the machine responds quickly and accurately, improving work efficiency.

Ideal for Multiple Attachments,

When a telehandler is equipped with multiple hydraulic attachments—like a bucket, clamp,

or jib boom—the electronic proportional valve ensures customized control for each function.

It allows operators to transition between tasks without losing performance or needing manual adjustments.

Reduced Maintenance,

This results in lower maintenance costs and longer service life.

3-ton telehandler forklift overall Size:

4780 mm*2180 mm*2580 mm (with fork length: 5890mm),

Fork length: 1220 mm,3t telehandler forklift. Self weight: 7450 kg.

Equipped with a Hose burst check valve and the Quick Hitch device.

What are the advantages of a Hose Burst Check Valve and Quick Hitch device on a telehandler forklift?

Modern telehandlers are expected to operate safely, efficiently, and flexibly.

By equipping your FLIFT telehandler forklift with a Hose Burst Check Valve and a Quick Hitch device,

you're significantly enhancing both operator safety and machine versatility.

Hose Burst Check Valve (HBCV): Enhanced Hydraulic Safety

A hose burst check valve is a critical safety component that prevents uncontrolled movement of the boom

or attachment in case of a hydraulic hose failure. It's especially important for machines lifting loads at height.

Benefits:

Prevents sudden load drop: If a hydraulic hose bursts or leaks, the HBCV locks the oil flow, preventing the boom or attachment from collapsing suddenly.

Protects people and goods: This ensures the safety of nearby personnel and protects valuable materials from damage.

Compliance with safety standards: Many international job sites require machines to have hose burst protection for insurance and safety compliance.

Peace of mind for operators: Knowing the load won't fall uncontrollably boosts operator confidence, especially in construction or high-lift operations.

Quick Hitch Device: Faster, Safer Attachment Changes

A quick hitch, also called a quick coupler, allows the operator to quickly swap attachments (like forks, buckets, clamps)

without needing tools or manual intervention under the boom.

Benefits:

Saves time: Attachments can be changed in minutes from inside the cab, significantly improving productivity.

Improves safety: Reduces the need for workers to manually change attachments under the boom, lowering the risk of injury.

Boosts flexibility: Operators can easily switch between lifting forks, buckets, truss booms,

or clamps depending on the task—ideal for mixed-use environments like farms or job sites.

Reduces labor: No extra hands are needed to change heavy attachments, making solo operation more efficient.

Feature Key Benefits,

Hose Burst Check Valve Prevents uncontrolled load drop, enhances safety, and protects the hydraulic system.

Quick Hitch Device: Faster attachment swaps, safer operation, increased job site efficiency.

Equipping your telehandler with these features shows that your machine is designed for real-world demands,

not just specs on paper. It enhances safety, productivity,

and flexibility—key decision factors for customers in construction, agriculture, logistics, and more.

Our FLIFT telehandler is equipped with the standard front-wheel steering, strong four-wheel steering, and crab drive function.

Steering Modes of Telehandler Forklift: Pros of Front-Wheel Steering, Four-Wheel Steering, and Crab Drive,

Modern telehandler forklifts are designed with multiple steering modes to adapt to different worksite conditions.

Here's how each mode improves your machine's performance, maneuverability, and safety.

Four-Wheel Steering (All-Wheel Steering),

In this mode, both the front and rear wheels turn in opposite directions to reduce the turning radius.

Tight turning radius: Great for navigating narrow aisles, congested worksites, or confined spaces.

Better maneuverability: Makes U-turns and repositioning easier and quicker.

Increased efficiency: Reduces the need for multi-point turns or reversing in tight areas.

Best for: Indoor operations, tight job sites, warehouse corners, or agricultural environments.

Crab Drive (Crab Steering Mode)

In crab mode, all four wheels turn in the same direction, allowing the telehandler to move diagonally like a crab.

Pros:

Reduces ground disturbance: Especially helpful on soft terrain where turning may damage the ground.

Best for: Working close to walls, maneuvering on construction sites, or accessing tight spaces without turning the body.

Why offer multiple Steering Modes for the telehandler forklift?

By equipping your FLIFT telehandler with these steering options, you give your customers:

Unmatched flexibility across different environments, more precise movement control for complex tasks, Improved safety, and reduced operator fatigue.

This versatility is a key selling point, especially for customers in construction, agriculture, logistics, and rental markets who need one machine that does it all.

What is a telehandler forklift used for?

A telehandler forklift, also known as a telescopic handler, is a highly versatile machine commonly used in construction,

agriculture, and industrial operations. It combines the lifting function of a forklift with the reach of a crane.

With its telescopic boom, the telehandler can extend forward and upward to lift and place materials at heights and distances that regular forklifts cannot reach.

Typical applications include:

Lifting and moving pallets of bricks or building materials on construction sites ,

Loading/unloading materials in warehouses or yards,

Its flexibility and reach make it a popular choice for jobs that require both vertical and horizontal material handling.

How high can a telehandler forklift lift?

The lifting height of a telehandler forklift depends on the specific model and boom configuration.

In general, most standard telehandlers can lift loads to heights ranging from 6 meters to 15 meters.

For example: Compact models may reach around 6–8 meters, Such as our FLIFT 3-3.5t telehandler forklift series.

Mid-range models typically lift to 12–15 meters.

Our 4-7t telehandler forklift series. Some telehandlers are even equipped with specialized booms or attachments for greater reach.

When choosing a model, it's important to consider the lifting height needed for your specific application.

whether you're stacking materials high on a job site or placing loads on multi-story buildings.

What is the weight capacity of a telehandler?

Telehandler forklifts come in a variety of load capacities to suit different work environments.

Most models can handle loads from 2,500 kg up to 5,000-7,000kg. Some heavy-duty models can lift even more,

depending on the boom extension and attachment being used.

Here's a general breakdown:

Small telehandlers: 2.5–3.5 tons,

What is the Maximum weight capacity of a telehandler lifting to the highest height?

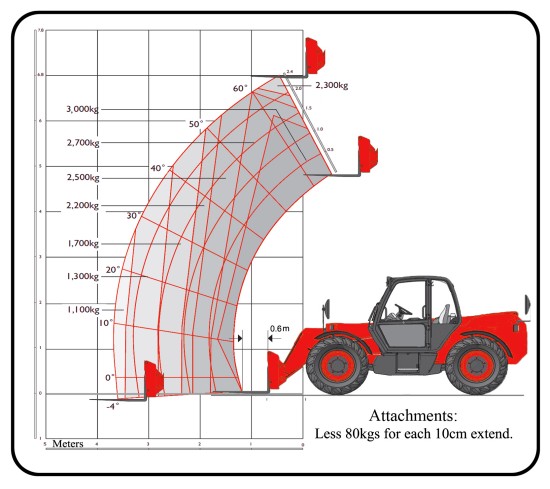

For example, our standard 3t telehandler forklift is equipped with a 2-stage 7m boom.

When this telehandler lifts to 7m, the corresponding capacity is around 1000 kg- 1500 kg.

Keep in mind that the lifting capacity decreases as the boom extends farther outward.

This is known as the load chart, and operators should always refer to it to ensure safe handling at various boom lengths and angles.

Can telehandlers be used on construction sites?

Yes, telehandlers are widely used on construction sites around the world.

Their ability to lift heavy materials to high places, combined with off-road capability and adaptability to various attachments,

makes them an essential piece of equipment for contractors.

On a construction site, a telehandler can:

Lift pallets of bricks, concrete blocks, or steel bars, and

Reach over uneven terrain or obstacles like trenches,

The all-in-one nature of a telehandler helps reduce the need for multiple machines, saving time and labor costs for construction crews.

What attachments can you use with a telehandler forklift?

One of the biggest advantages of telehandlers is their attachment versatility.

Depending on the job, operators can switch out the attachment at the boom's end to transform the telehandler into a different kind of machine.

Common telehandler attachments include:

Pallet forks–for standard lifting and transporting pallets,

Rotator attachment- An attachment install together with forks. Has the rotate 360°function.

Buckets–for scooping gravel, soil, or debris and Lifting hooks or jib booms–for hoisting heavy or awkward loads.

Work platforms–allowing workers to access elevated areas,

Truss booms–for lifting and placing large trusses or beams.

This versatility makes the telehandler useful in many industries, from agriculture and landscaping to mining and building construction.

Does a telehandler have 4-wheel drive or all-terrain capability?

Yes, most modern telehandlers are built with 4-wheel drive and all-terrain capability.

This allows them to operate efficiently on rough, uneven, or muddy surfaces, which are common on job sites, farms, and outdoor yards.

Key features that enable this performance include:

High ground clearance to avoid getting stuck or damaged,

Large, rugged tires that grip well on dirt or gravel,

Powerful engines and drivetrains for climbing slopes or hauling loads,

Four-wheel steering on some models, which improves maneuverability in tight spaces.

These features make telehandlers suitable for off-road environments where traditional forklifts would struggle to move safely or effectively.

this machine is engineered for efficiency.

Equipped with a YUCHAI diesel engine and an advanced joystick design featuring an electronic proportional valve,

experience smooth control like never before. Don’t miss out on seeing it in action—watch the video now!

"Revolutionize Your Load Handling: Meet the FLIFT 3T Telehandler Wonder!"

.png)